Announcements

10/04/2023

Reading time: 7 min

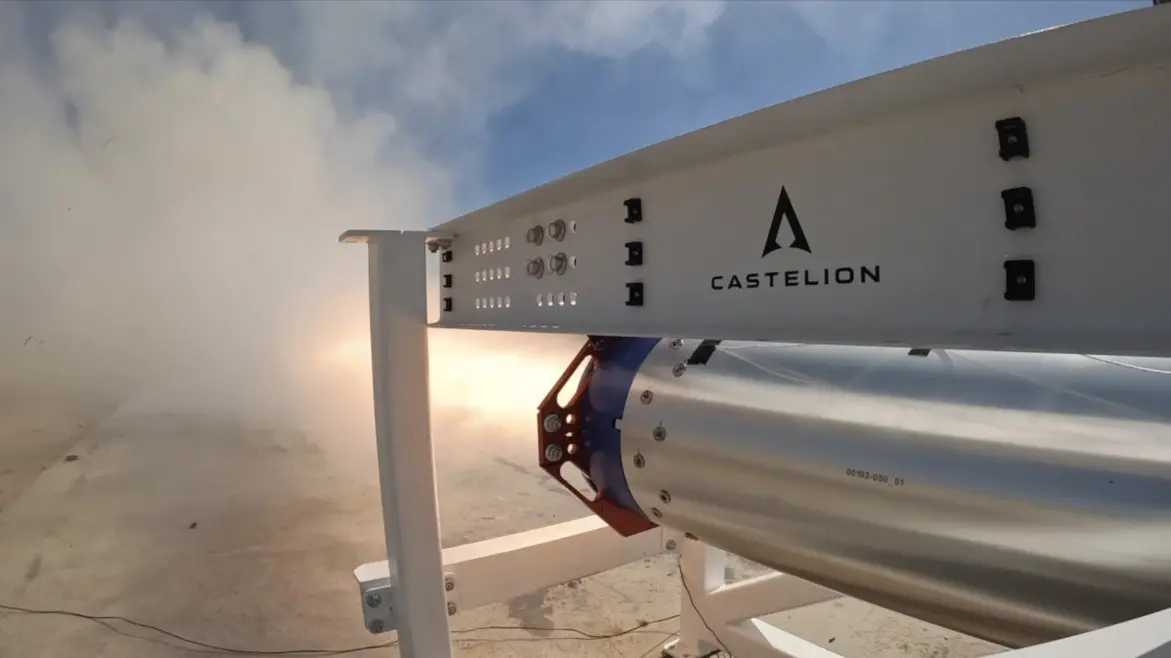

Announcing Castelion

For the past three decades, our world has experienced a unique period of relative peace between major powers stemming from an overwhelming military advantage in the hands of nations who advocate for and represent free and open societies. Today, this state of relative global security is in jeopardy as nations that are threatened by the concepts of democracy and open society are achieving a pace of military production and innovation that frequently surpasses our own. To counter this growing threat, and to support democracy for generations to come, America’s defense industry needs new technologies, new manufacturing approaches, and new ideas to stay unequivocally ahead. That’s why, in November 2022, we founded Castelion – a new kind of defense manufacturing company.

For the past three decades, our world has experienced a unique period of relative peace between major powers stemming from an overwhelming military advantage in the hands of nations who advocate for and represent free and open societies. Today, this state of relative global security is in jeopardy as nations that are threatened by the concepts of democracy and open society are achieving a pace of military production and innovation that frequently surpasses our own. To counter this growing threat, and to support democracy for generations to come, America’s defense industry needs new technologies, new manufacturing approaches, and new ideas to stay unequivocally ahead. That’s why, in November 2022, we founded Castelion – a new kind of defense manufacturing company.

Castelion is focused on the rapid development and mass manufacturing of complex defense systems, with an emphasis on schedule, affordability, and scale – the critical components of maintaining the military advantage needed for a lasting and enduring peace.

We’ve been heads down focused on early results, but today are excited to exit this initial stealth phase and announce our initial $14.2M of funding co-led by Andreessen Horowitz and Lavrock Ventures. This capital, in conjunction with existing US Government contracts, will accelerate our efforts to design, build, and test capabilities that make affordable and timely overmatch possible.

America spends too much on defense to get so little in return. America can do better.

The current cost and cycle time required to develop and maintain defense hardware in the United States is unsustainable, and worse, it doesn’t keep pace with the speed and cost of development efforts abroad.

Despite the U.S. annual defense budget exceeding those of the next ten biggest spenders combined, there’s irrefutable evidence that authoritarian regimes are taking the lead in key military technologies like hypersonic weapons. Simply put – this cannot be allowed to happen.

The American defense industry has now slid into a pattern of industry consolidation, ballooning program costs, and endless production delays – all of which have left our nation in a worse position to protect democracy and confront our adversaries around the world. The means, methods, and technology of conflict are rapidly changing and, to deter future wars, so must we. This requires a step-function improvement in defense production.

So, how did we get here?

The defense industry has undergone round after round of consolidation, leaving us with a dwindling set of viable competitors for multi-billion-dollar defense contracts. In nearly all cases, there are oligopolies – and in many cases monopolies – responsible for producing key defense systems. The collapse of competition has led (as it always does) to high prices for taxpayers and poor performance for warfighters.

While we don’t believe that any individual company has mal-intent, we recognize that competition is essential to a healthy industrial base and forces an urgency to innovate.

Despite this widespread consolidation – always touted as improving efficiency through scale – remaining industry players have rapidly moved away from actually building the systems they’ve been contracted to build.

Today, defense primes are primarily system integrators, not manufacturers. They purchase and combine components from hundreds or even thousands of suppliers to assemble a final product instead of building it themselves. They then pass the cost of overhead and profit from those thousands of suppliers, plus the cost of their own large and cumbersome internal management bureaucracy, onto the taxpayer. The ability to produce faster, change direction, and meaningfully cut costs in such an environment is exceedingly difficult.

This devolution of leading defense companies from manufacturers to system integrators is further enabled by the overuse of cost-plus contracts. The ubiquity of this contracting method reinforces this costly slide away from manufacturing by disincentivizing contractors to increase efficiency and, without competition in the market, again results in suboptimal outcomes for the warfighter and the taxpayer.

We simply cannot compete against a lean and fast-moving adversary if we maintain this approach.

Looking back to move forward

There are ample historical examples of the ability of American industry to give our armed forces the capabilities they need – in relevant quantities and time frames – to win on the battlefield. Our nation achieved a clear advantage in previous conflicts by emphasizing development speed, iteration, and mass production, apparent in the development of early warning radar, the proximity fuse, and the B-24 Liberator, and Castelion believes this approach is once again critical to winning today.

At Castelion, we’re inspired by these development stories, like that of the P-51 Mustang, where in the face of a grave threat in 1940, North American Aviation successfully delivered a prototype for the brand-new fighter just 117 days after receiving an order – and started flying the plane that turned the tide of the air war over Europe just 6 weeks later.

At Castelion, we believe there’s no reason that development and production stories like this must live in the past.

The Castelion approach – what makes us different

Agile Hardware Development.

American leadership depends on industry to develop and deploy leading capabilities in months, not decades. At Castelion, we embrace a different approach to achieving this outcome.

- Set aggressive targets – you don’t achieve what you weren’t trying to do

- Hardware-rich development to validate assumptions, unknowns, and design choices constantly

- Make choices that increase the velocity of design-build-test cycles

- Assume all early designs will be suboptimal, no matter how great the engineering that created it

- Product owners also own manufacturability and cost outcomes, it isn’t another team’s issue to solve

- Best idea wins, but be prepared to take the entire team on a trip to Missouri (the Show-Me State)

Vertical Integration to Control Schedule.

The major driver of ballooning defense program costs is not the cost of material and hardware, but the labor associated with protracted development and production timelines. We view vertical integration through a lens of speed to mass production.

- Embrace the non-intuitive truth of large programs that faster is almost always cheaper

- Labor costs are so dominant on complex development efforts that it is almost never right to outsource if it increases schedule

- If using a supplier on a key subsystem, always ensure they can keep up with frequent design iterations

- Avoid introducing single points of failure in the supply chain that threaten the hardware-rich, high cadence development approach

Hardware Designed for Production at Scale.

At Castelion, we’re focused on providing the capabilities America needs to achieve peace through a credible, non-nuclear deterrent.

- Plan to produce hardware at a rate necessary to achieve the national strategic outcome, not the immediate requested quantity

- It isn’t a success unless America can afford the quantities needed to achieve deterrence

- Optimizing for cost and manufacturability is an eternal task

Castelion is returning to the manufacturing approach used in the heyday of American defense innovation and we’ll be moving fast.

Stay tuned to our blog to stay abreast of our latest activity and consider joining us if our vision of building a lasting peace resonates with you – let’s build!